How do Roots Blowers work?

Roots Blowers are consist of two rotors inside the pump housing. The two rotors are mounted on parallel shafts. Rotors rotate non-contact at the same speed in opposite directions in order to draw air or gas into the blower body. A set of timing gears keeps the rotors in synchronization. Driving air or gas at the inlet side is trapped between the rotors and the casing. The rotating rotors pushes the trapped air or gas to the discharge side against whatever pressure exists in the system.

One rotor is called the “driving rotor” because it is run by an external power supply – generally an electrical motor-, while the opposite rotor is called a “driven rotor” because it is driven by gears connected to the driving rotor.

Why are they classified in Positive Displacement Pump?

Once the rotors open to the outlet side, the discharge line equalizes the pressure of the air and is forced out of the blower. The air is unable to come back due to the small amount of internal clearance between the internals of the machine. This process enables the blower to overcome line pressure hence the name positive displacement. Put differently, the volume of air does not change within the device, but is rather displaced from one end of the machine to the other.

What is Roots Blower?

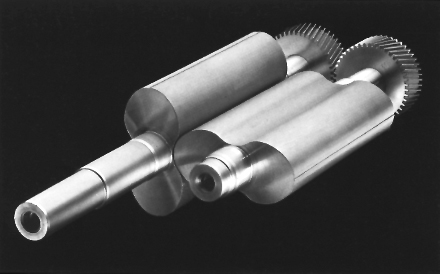

Roots Pump Blower consists of two pieces twin-lobe or three-lobe rotors which are non-contact and rotated in opposite directions each other within the pump housing. As a result of rotating rotors in opposite directions, intake air is evolved pressure air and blowing outside.

Roots Pump Blower is a positive displacement pump and probably the most commonly used type of compressor in conveying systems. Roots Pump Blower is employed for many industrial processing. Due to flexible construction system, it is possbible to mount all corresponding blowers and motor sizes either with belt or direct coupling. Housing parts made of alloyed cast iron adn rotating parts also made of special alloys having very upgraded designs.

Compressor Types

The compressors are divided into two parts:

1.Dynamic Compressors

a. Axial Compressors

b. Centrifugal Compressors

2. Positive Displacement Compressors

a. Roots Blowers

b. Reciprocating Compressors

c. Screw Compressors

What is Compressed Air?

Air whose density is increased by subjecting it to a pressure greater than atmospheric pressure.

What is Compressibility?

The property of a substance capable of being reduced in volume by application of pressure; quantitively, the reciprocal of the bulk modulus.

What is Volume Flow Rate?

Volume flow rate measurements are necessary in many industrial processes to keep track of the amount of material being transported from one point to the next point in a plant.

The volume flow rate is simply defined by the volume of a given substance that flows through something per unit time.

volume flow rate = volume/time