PASIFIK BLOWER MODELS

PB100

Power range is from 0,75 kW to 5,5 kW. Air flow rate is from 70 to 170 m3/h. and pressure level is up to 800 mbar.

|

PB112

Power range is from 0,55 kW to 11 kW. Air flow rate is from 45 to 324 m3/h. and pressure level is up to 900 mbar.

|

PB125

Power range is from 1,5 kW to 30 kW. Air flow rate is from 174 to 900 m3/h. and pressure level is up to 800 mbar.

|

PB137

Power range is from 4 kW to 45 kW. Air flow rate is from 390 to 1400 m3/h. and pressure level is up to 800 mbar.

|

PB151

Power range is from from 7,5 kW to 90 kW. Air flow rate is from 1.270 to 2.530 m3/h. and pressure level is up to 1000 mbar.

|

PB161

Power range is from from 15 kW to 250 kW. Air flow rate is from 2.775 to 7.650 m3/h. and pressure level is up to 800 mbar.

|

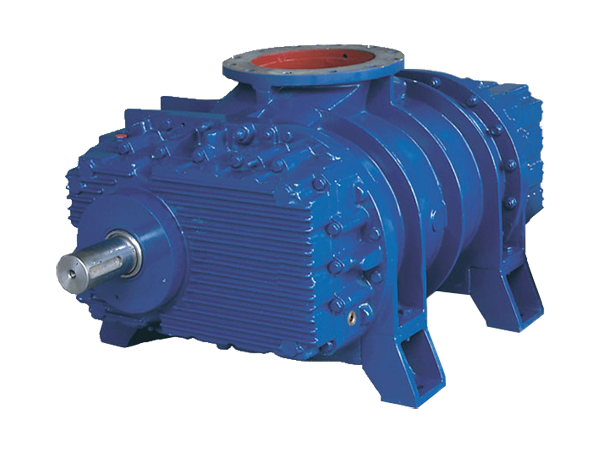

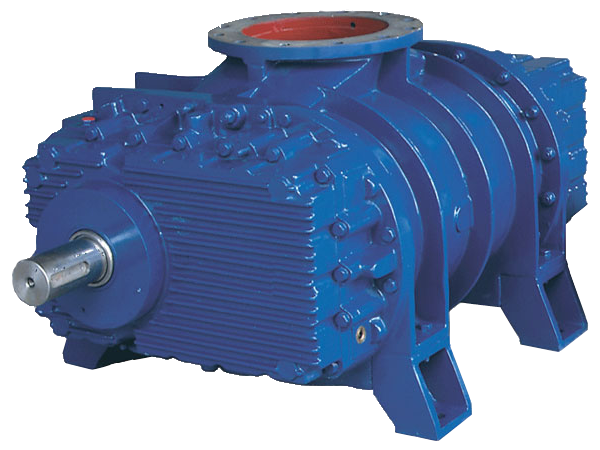

Pasifik Blower at a Glance

Roots Pump Blower consists of two pieces twin-lobe or three-lobe rotors which are non-contact and rotated in opposite directions each other within the pump housing. As a result of rotating rotors in opposite directions, intake air is evolved pressure air and blowing outside.

Roots Pump Blower is a positive displacement pump and probably the most commonly used type of compressor in conveying systems. Roots Pump Blower is employed for many industrial processing. Due to flexible construction system, it is possbible to mount all corresponding blowers and motor sizes either with belt or direct coupling. Housing parts made of alloyed cast iron adn rotating parts also made of special alloys having very upgraded designs.

Pneumatic Conveying

Pneumatic conveying or pneumatic transport is a system or a process in order to transfer the bulk materials whatever they are granular or powdered through pipeline using pressured or vacuumed gas (usually air) which is generated by a suitable roots blower or compressor.

Water Treatment

Roots blowers are both employed to aerate grit chamber in order to prevent sinking to the bottom of wastewater and blow air to aeration unit for bacteria to live in water treatment units. Number and size of blowers should be selected according to the capacity of the facility.

Chemical Industry

Roots blowers are employed in chemical and petro-chemical industry for conveying and compressing of many kind of gases that are inert, corrosive and explosive. Besides, the chemical and petro-chemical industry particularly depends on the gas supplying for their processes.

Food Industry

Foods must be clean and healthy. Therefore, both raw materials and finished products should be zero-touch during production. Blowers provides to convey pneumatically both raw materials and finished products like as sugar, salt, flour, grains, milk powder, chocolate etc. by reliable and clean way.

Marine Industry

Rotary air blowers are used as supercharging of diesel engine, providing air supply to bubbler systems to Arctic duty vessels and icebreakers, for pneumatic transportation on ships, for maintaining ice-free ports, providing air bubble curtains (creating sound protection) to protect marine life.

Mining Industry

Roots blowers are used in mining industry for pneumatic transport of bulk materials and minerals. It is also used in aeration for oxidation processes and other refining applications. And especially big mining areas have wastewater treatment facilities where the roots blowers are employed.

Vacuumed Air in Industry

Roots blowers are almost used in vacuum systems where large gas loads are pumped in the intermediate vacuum range and/or volumes must be evacuated in a relatively short time. Vacuum systems are used in different manufacturing processes in many industries and areas.

Biogas Recovery

Biogas is primarily methane (CH4) and carbon dioxide (CO2) and may have small amounts of hydrogen sulfide (H2S), moisture and siloxanes. Biogas is explosive and corrosive. Roots blowers are used to convey biogas through pipes to burner or recirculated to fuel combustion engine-driven machines.

Mounted on Bulk Trailers

Roots blowers are also used as mobile. Roots blowers are mounted on bulk trailers in order to blow feed, grain or cement from the trailer into bulk hoppers, bins or silos. They are also used to blow feed, grain or cement from hoppers, bins or silos into trailer.

Pasifik Blower Capacity Range

Highly-Developed Design

Because of highly-developed design of Pasifik Blowers that are suitable for extensive range of industrial applications and hard working conditions.

Wide Range Models

Wide range of our Roots Blowers and accessories are available depending on process parameters and operating environment. Our six models are ready to serve you.

Low Maintenance

We engineered our machines to outperform and provide you with years of easy upkeep. We deliver more reliable and efficient roots blowers to you thanks to its rigid cast iron casing.

Heat Dissipation

Overheating of most machines is generally undesirable situation. We prevent to overheat thanks to ribbed blower body for high efficiency heat dissipation.

Spare Parts Availability

We at Pasifik Blower produce every single parts of our blowers by ourselves. What parts of our blowers you need, we guarantee that we can quickly supply it.

Oil-Free Operation

Because the rotors operating non-contact each other and blower housing, no lubrication is required. This feature provides a great advantage in applications that need clean air or gases.